-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

REAP

Real-time Diagnostics for Enabling Advanced Laser-based Roll to Roll Materials Processing

The Marie Sklodowska Curie Individual Fellowship enables Dr. Nazar Farid to relocate to the NCLA Laser Laboratory at NUI Galway Ireland. Dr. Farid is an experienced researcher with laboratory expertise in real time monitoring of laser-matter-ambient-interactions. The objective of the project is to identify how real time or in-line diagnostics can fully realise the potential of short pulse laser structuring of materials. An active programme of research, knowledge transfer and information dissemination is being undertaken which centres on the development of new laser process tools for future roll to roll large area electronics.

Key achievements

- Clean laser nanostructure-enabled patterning & selective etching of indium tin oxide.

- New laser process for submicron structuring of glasses.

- New process for laser metal induced crystallinity.

- Demonstration of process monitoring on graphene / ITO.

Real-Time Monitoring

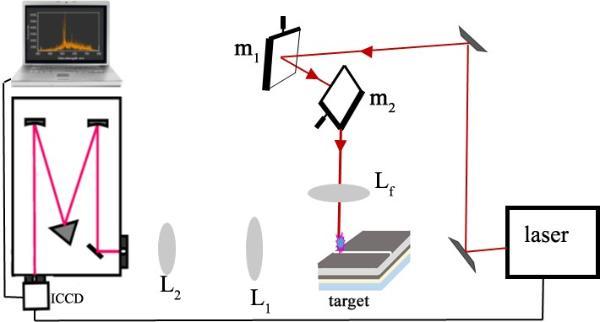

Schematic of apparatus for real time monitoring coupled to laser ablation used to optimise laser processes in the project.

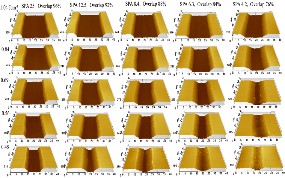

Laser Patterning of Thin Films

Repetitively pulsed, short and ultra-short, pulse laser technology offers an alternative to other chemical processes for patterning of thin films. The image show selective patterning of the transparent conductive material, indium thin oxide (ITO), on thin glass substrates relevant to OLED, photovoltaic and touch panel devices.

Galway Science Festival 2016

Dr. Nazar Farid demonstrating his research at the Galway Science Festival November 2016.

|

|

|

Acknowledgements

The Fellow is grateful for the support of Andor Technology Ltd. (Belfast, Northern Ireland) who provided access to the process monitoring tools. The support of laser systems integrator M-Solv (Oxford, England) Ltd. is also acknowledged. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 659454

|

|

||

|

|

||

|

|