-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

MSc in Key Enabling Technologies (KETs)

Key Enabling Technologies are recognised by the European Union to be the building blocks for future product and process technologies. Europe’s future competitiveness depends on how its labour force will apply and master the fusion of two or more key enabling technologies on advanced manufacturing test-beds. This interdisciplinary programme prepares technologists for this societal challenge.

The six key enabling technologies are:

- Photonics

- Advanced Materials

- Industrial Biotechnology

- Advanced Manufacturing

- Nanotechnology

- Micro- / Nano- electronics

The M.Sc. programme provides students with structured training in Scalable Innovation and Laser-enabled bioprinting. This training is underpinned by advanced courses in Optical Design, Advanced Materials, and Tissue Engineering. The programme is particularly focused on digital additive and subtractive processes –targeting personalised medical devices and sensors –pivotal for addressing future key healthcare challenges. Students will gain hands on experience on state of the art manufacturing research platforms enabling them to demonstrate their research potential.

The programme is an ideal opportunity for launching a career in research for industry or academia; it is informed by the goals of three key Science Foundation Ireland Research Centres, CÚRAM Centre for Medical Devices, I-FORM Centre in Advanced Manufacturing and the IPIC Centre in Photonics Technologies.

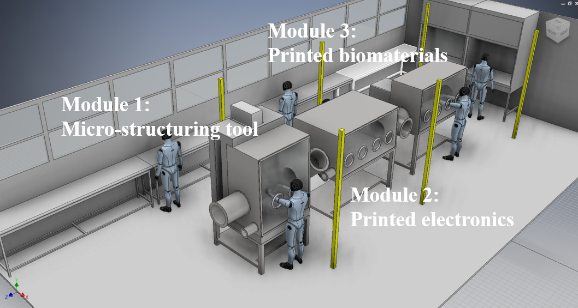

New Development for 2018/2019

Proposed new Science Foundation Ireland funded Laser-Enabled Additive and Subtractive Pilot Manufacturing Test-bed, to be commission July 2018/2019, on which future MSc training will be undertaken.

Strategic Focus 2018/19

Students work on individual research projects aligned with a team-based challenge. All projects will converge towards the central theme encompassing the application of multiple key enabling technologies to create electrically, optically and thermally activated medical device concepts using an additive (inkjet & spray) and subtractive (laser) advanced manufacturing test-bed.

Applicants interested in the integration of flexible microfluidics, with laser-enabled printed electronics and soft biomaterials, are particularly encouraged to apply for academic year 2018/19. The programme is ideally suited to a career in biomedical engineering science

Entry Requirements

Students with a 2.1 honours degree, or higher, in Science or Engineering (level 8) will be considered for this programme. Students with a 2.1 grade from the pen ultimate of the BSc or BEng programme at NUI Galway will be given a provisional offer of a place on the programme, on completion of an interview. There will be a proposed quota of 5 students and a limit of 10 students in 2018/2019.

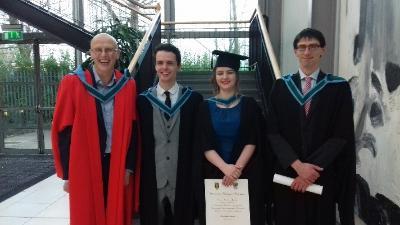

Graduation 2017

Dr Gerard O'Connor, Emmett Gallagher, Lisa Faherty, Darren Molloy

Gerard O’Connor |

Programme director, expertise in Photonics, Advanced Manufacturing and Micro - Nano-Electronics |

Patricia Scully |

Expertise in Photonics, Micro- / Nano-electronics and Advanced Manufacturing. |

Yury Rochev |

Expertise in Advanced Materials and Industrial Biotechnology |

Manus Biggs |

Expertise in Advanced Materials, Industrial Biotechnology and Nanotechnology. |

Jessamyn Fairfield |

Expertise in Nanotechnology, Micro - Nano-Electronics, and Advanced Materials |

Noel Harrison |

Expertise in Advanced Manufacturing and Advanced Materials |

|

Darren Molloy, 2016/17 Project Leader Amatech Group Darren developed a laser based process to fabricate antennae and heater elements to create a wireless heater component for a microfluidic device. Antennae based microheater left with thermal image right |

“During the course, I found that the level of practical experience working in the high-tech environment greatly beneficial. The course has a strong focus on innovation and working in an industry-style setting. The work placement module provided opportunities to meet and connect with companies related to my career. Since finishing my M.Sc. the knowledge and experience gained has undoubtedly advanced my career. I am now a project leader for the R&D department and feel more equipped to handle the challenges of the job. I have been able to incorporate new methods and processes that were developed through the M.Sc. programme. This has also opened doors to the possibilities of doing a PhD in the future, and has given me the confidence to pursue further education." |

|

Ciaran Feeney 2015/16 Manufacturing Engineer Valeo, Galway. Ciaran’s project investigated laser hydrogel film interactions using ultrashort pulses for selective structuring. The project created a patterned thermally responsive polymer for future therapeutic applications. Laser patterned PNIPAM thin coating. |

“I decided to study a MSc. in KETs as the strong focus on research and independent laboratory work very much appealed to me. I also relished the chance to work in a high technology environment where I had the opportunity to work with advanced laser systems and characterization tools. Throughout the programme I gained an appreciation for how research is translated into the processes used in the creation of products. It helped me to bridge the disconnect between how the experimental work I performed in my research impacts the end user application. This was an understanding that was absent in my undergraduate experience and one which I think isn't emphasised enough in science degrees. I now realise the importance of creating value at the various stages in the chain of activities and this in turn influences my decision-making and actions in my day to day work. I'm now currently employed in the rapidly expanding autonomous driving industry. The pace at which technologies change in the sector requires us to be adaptable and able to adopt the new techniques developed in R&D. In this environment, I've found the MSc. in KETs to have been massively beneficial as it has equipped me with the appropriate mindset in an industry where the need to need to apply the technology developed internally is crucial for staying competitive.” |

|

Lisa Faherty 2016/17 Research Assistant, School of Physics, NUI, Galway.

Lisa’s research project developed ultrasonic spray deposition processes for biomaterials. Thermal and high speed imaging of ultrasonic spray tool. |

“After graduating from my undergraduate degree I knew I had a strong interest in the medical devices but didn’t know how to enter the area. The MSc. KETS programme seemed like a perfect fit. The research focus of the programme allowed me to develop my critical thinking and research skills and the modules available also helped me to expand my skill set and allowed me to learn about other KETs research currently in progress in Ireland. Through my project I discovered a great interest in the area of additive manufacturing and I gained experience and knowledge in advanced manufacturing and characterization techniques. I enjoyed the ability to take a recently purchased spray coating system and investigate its strength and weaknesses. This project allowed me to thoroughly understand ultrasonic spray coating and dip coating and allowed me to develop a good understanding of the fundamental principles involved in the coating of materials. I believe the investigative, characterization and independent research skills I have developed are key to entering the medical device area. I am currently further exploring this interest in advanced manufacturing techniques as a Research Engineer on a European research project.”

|

|

Peter McGlynn 2015/16 PhD Researcher CÚRAM Medical Devices NUI, Galway Peter’s MSc project developed and analysed the creation of microheaters on thin glass materials. Reconfigurable fabrication of variable temperature microheaters |

“Following the completion of a B.Sc. in Applied Physics, I was looking for an opportunity to gain more laboratory and research experience, particularly in the fields of advanced manufacturing and materials for medical devices. The M.Sc. in Key Enabling Technologies (KETs) provided this opportunity and allowed me to learn and gain experience in industrially relevant advanced manufacturing processes and characterisation techniques. The course appealed to me as the research is driven by innovative and competitive strategies which were studied during the programme; this provides significance to the work being carried out and has provided me with knowledge to succeed in industry. The project involved the use of various advanced laser and characterisation systems for the fabrication of a microheater platform. It gave me the chance to work in collaboration with esteemed researchers in Spain where the platform was investigated for cell culture applications. The work carried out during the programme lead to a collaborative research publication and established a funded PhD research opportunity which now allows me to continue research into manufacturing techniques for the medical device industry.” |

|

Maureen Fitzpatrick 2015/16 Engineer, Analog Devices, Limerick. Maureen’s project developed the application of a mechanically inspired laser scribing process for thin flexible ceramics. Mechanically inspired laser scribing of thin flexible substrates. |

“The leading-edge research that was being carried out in the National Centre for Laser Applications at the School of Physics in NUIG was what first attracted me to the MSc KETs programme. I was fairly indecisive about which career path I wanted to pursue upon finishing my undergrad at McMaster University (Canada). I knew I was passionate about photonics and taking on a postgraduate degree in the field was definitely on the cards, but I was nervous about not going into industry and getting experience in a workplace. The MSc KETs programme; was the perfect compromise –a one year programme to attain a research Master’s enabling me to discover my research potential in the most efficient manner available. I was given the freedom to define my own project and with the guidance of my supervisor, Ger O’Connor, was able to make sure this project aligned with the direction that other research in the field was converging towards. Every week I carried out experiments in a few different labs with the assistance of technicians, my fellow MSc KETs candidates, and other more experienced students; which helped maintain the momentum of the project and shorten the time to getting results. I was also able to make contributions to the scientific community by giving an oral presentation at the European Materials Research Society conference in France and by participating in a successful submission of a paper publication to a reputable journal. These were goals that I communicated to my supervisor at the start of the year and he was extremely helpful in seeking out these opportunities for me. The research Master’s definitely helped me realise that if desired, I felt I was capable of taking on a PhD. However, despite being awarded a prestigious Irish Research Council Enterprise PhD Scholarship, I decided to take a position as an electronics engineer at Analog Devices in Limerick. Even though this job isn’t in the same field as the MSc KETs, the programme taught us transferrable skills, like how to set up and execute experiments as well as how to make good business decisions, which I know will be helpful in any career I choose moving forward.” |

Publications with major contributions by students undertaking the MSc in Key Enabling Technologies

Keenan, E., Gethin, G., Flynn L., Watterson, D., O'Connor, G.M. Enhanced thermal imaging of wound tissue for better clinical decision making Physiological Measurement, 38(6) 2017 1104-1115

Nieto, D., McGlynn, P., de la Fuente, M., Lopez-Lopez, R., O’Connor, G.M., Laser microfabrication of a microheater chip for cell culture outside a cell incubator, In Colloids and Surfaces B: Biointerfaces, Volume 154, 2017, Pages 263-269

Collins AR, Fitzpatrick MA, Trollat J-L, Olenick K, Olenick J, O'Connor GM. Mechanically inspired laser scribing of thin brittle materials. J Am Ceram Soc. 2017: 100:5318–5326.

Previous graduates & project titles

|

Ciaran Feeney, |

Hydrogel Film Laser Interaction with Ultrashort Pulses for Selective Structuring |

|

|

Peter McGlynn, |

Development of Integrated Thin Film Heating Elements for Thermal Activation in Custom Multifunctional Components |

|

|

Maureen Fitzpatrick, |

Mechanically Inspired Laser Scribing of Thin Flexible dielectrics |

|

|

Ellen Keenan, |

Physical Interpretation of Infrared Imaging of Wounded Tissue |

|

|

Emmet Gallagher, |

Laser Processing of PMMA to Enable Fabrication of PDMS Microfluidics for Bone-on-a-Chip Applications |

|

|

Lisa Faherty, |

Development of a MultiCoater System for the Creation of Uniform PEGDA films |

|

|

Darren Molloy, |

A Laser Based Process to Fabricate Antennae and Heater Elements to Create a Wireless Heater Component for A Microfluidic Device |

|