-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

Falcom

Advancing Hybrid Composite-Metal Joining Technology

Composites are advanced materials with very high strength-to-weight ratios, and so are being introduced into virtually all weight sensitive structures. To support this integration, new highly efficient joining technologies are urgently required. Composites joining technology is fundamental to engineering and manufacturing. Without the ability to make strong and durable connections between materials it would not be possible to produce the many different items upon which we all rely on in our everyday lives.

The FALCOM project is a collaboration between the NCLA and the Bernal Insititute in University of Limerick that seeks to develop a new state-of-the-art fastener-less joining technology to join composites to metals which does not require any mechanical fastening. Novel interlocking surface profiles will be designed, optimised and cast using novel composite processing techniques and laser etched into composite and metal surfaces, to form hierarchical structured surfaces. New reversible adhesives will be developed to bond and seal these interlocked surfaces, to result in highly durable joints that are fully reversible. This will be a highly novel development, and would be highly advantageous to manufactures and consumers in both the assembly and disassembly of components.

Project Partners:

|

|

|

| National Centre for Laser Applications,NUI Galway | Bernal InstituteUniversity of Limerick |

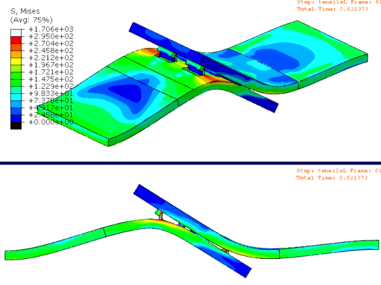

Computer Modelling of Joint

Computer based modelling of interlocked joint in CFRP

3D Array

Laser machined features in CFRP

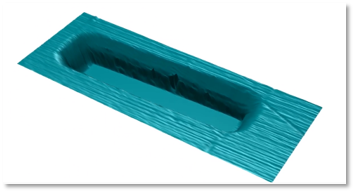

Laser machined 3D Component

Laser machined twisted plug in CFRP

Micro CT of 3D Feature

Micro CT image of laser machined feature in CFRP

|

|

|